Crankshaft Grinding Machine Working Principle . the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. when choosing a crankshaft. crankshaft grinding consists of removing a minute amount of finished. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital. 2.1 crankshaft grinding machine dimensional error monitoring and dynamic compensation principle. crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to rebuild the part. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring and eccentric.

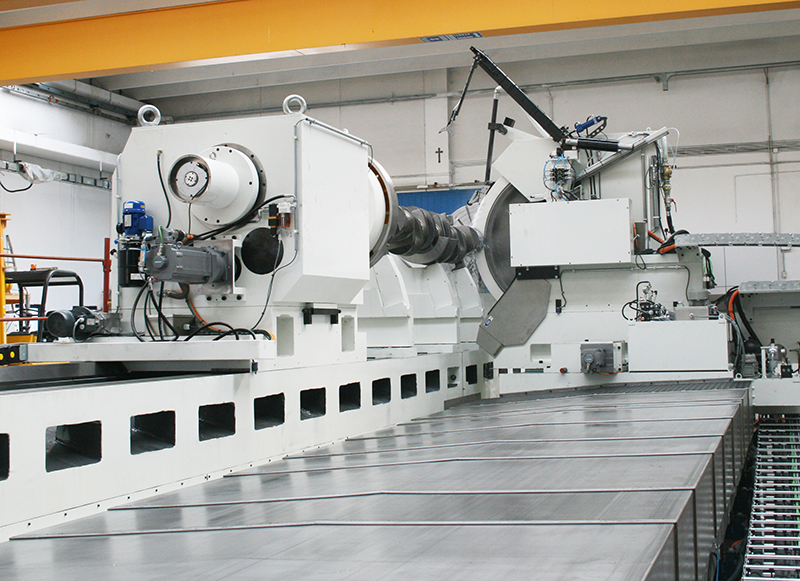

from www.azspa.it

grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital. when choosing a crankshaft. crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to rebuild the part. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring and eccentric. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. 2.1 crankshaft grinding machine dimensional error monitoring and dynamic compensation principle. crankshaft grinding consists of removing a minute amount of finished.

DB CNC Orbital Heavy Duty Crankshaft Grinding machine

Crankshaft Grinding Machine Working Principle crankshaft grinding consists of removing a minute amount of finished. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. crankshaft grinding consists of removing a minute amount of finished. crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to rebuild the part. 2.1 crankshaft grinding machine dimensional error monitoring and dynamic compensation principle. grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring and eccentric. when choosing a crankshaft.

From www.newkidscar.com

Crankshaft construction and Related Parts Car Construction Crankshaft Grinding Machine Working Principle 2.1 crankshaft grinding machine dimensional error monitoring and dynamic compensation principle. crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to rebuild the part. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. grinding a crankshaft is a process. Crankshaft Grinding Machine Working Principle.

From www.howacarworks.com

How the crankshaft works All the details How a Car Works Crankshaft Grinding Machine Working Principle crankshaft grinding consists of removing a minute amount of finished. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring and eccentric. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. 2.1 crankshaft grinding machine dimensional. Crankshaft Grinding Machine Working Principle.

From ecomachinetools.com

Crankshaft Grinders CNC Crankshaft Grinding Machine Crankshaft Grinding Machine Working Principle when choosing a crankshaft. crankshaft grinding consists of removing a minute amount of finished. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring and eccentric. 2.1 crankshaft. Crankshaft Grinding Machine Working Principle.

From www.youtube.com

NEW MODEL OF CRANKSHAFT GRINDING MACHINE YouTube Crankshaft Grinding Machine Working Principle the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. when choosing a crankshaft. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. 2.1 crankshaft grinding machine dimensional error monitoring and dynamic compensation principle. crankshaft grinding. Crankshaft Grinding Machine Working Principle.

From pt.slideshare.net

Chapter 25 (grinding) Crankshaft Grinding Machine Working Principle the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as. Crankshaft Grinding Machine Working Principle.

From tuffclassified.com

Free Classifieds Ads In India Buy/Sell/Rent Tuffclassified Crankshaft Grinding Machine Working Principle crankshaft grinding consists of removing a minute amount of finished. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. 2.1 crankshaft grinding machine dimensional error monitoring and dynamic compensation principle. grinding a crankshaft is a process of removing material from the journals in an effort to refurbish. Crankshaft Grinding Machine Working Principle.

From www.youtube.com

Offset Grinding Crankshaft YouTube Crankshaft Grinding Machine Working Principle grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. when choosing a crankshaft. the work was performed with grinding machine type db12500,. Crankshaft Grinding Machine Working Principle.

From finemetalworking.com

What is Centerless Grinding? How Does the Machine Work? Crankshaft Grinding Machine Working Principle the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring. Crankshaft Grinding Machine Working Principle.

From www.youtube.com

CGA270 Crankshaft grinding machine YouTube Crankshaft Grinding Machine Working Principle crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. when choosing a crankshaft. crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to rebuild the part. the work was performed with grinding machine type db12500, equipped with. Crankshaft Grinding Machine Working Principle.

From www.crankshaftgrindingmachine.com

Blog Crankshaftgrindingmachine Crankshaft Grinding Machine Working Principle the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring. Crankshaft Grinding Machine Working Principle.

From www.emag.com

Crankshaft grinder PM 2 for crankshaft grinding Crankshaft Grinding Machine Working Principle when choosing a crankshaft. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control. Crankshaft Grinding Machine Working Principle.

From www.alamy.com

Precision grinding a car engine crankshaft on a crank grinding machine Crankshaft Grinding Machine Working Principle grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing. Crankshaft Grinding Machine Working Principle.

From www.youtube.com

Crankshaft Grinder YouTube Crankshaft Grinding Machine Working Principle 2.1 crankshaft grinding machine dimensional error monitoring and dynamic compensation principle. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. grinding a crankshaft is a process of. Crankshaft Grinding Machine Working Principle.

From jackquelinebritt.blogspot.com

surface grinding machine parts and functions Jackqueline Britt Crankshaft Grinding Machine Working Principle crankshaft grinding consists of removing a minute amount of finished. grinding a crankshaft is a process of removing material from the journals in an effort to refurbish and reuse an expensive, yet vital. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring and eccentric. crankshaft grinding. Crankshaft Grinding Machine Working Principle.

From www.technologystudent.com

The Shaping Machine and its Mechanism Crankshaft Grinding Machine Working Principle the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. crankshaft grinding is a critical precision machining process that plays a vital role in the manufacturing of internal combustion engines. crankshaft grinding consists of removing a minute amount of finished. when choosing a crankshaft. grinding a crankshaft. Crankshaft Grinding Machine Working Principle.

From www.youtube.com

AUTOMATIA CRANKSHAFT GRINDER WORKING VIDEO YouTube Crankshaft Grinding Machine Working Principle 2.1 crankshaft grinding machine dimensional error monitoring and dynamic compensation principle. crankshaft grinding consists of removing a minute amount of finished. crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to rebuild the part. when choosing a crankshaft. grinding a crankshaft is a process of removing material. Crankshaft Grinding Machine Working Principle.

From www.theengineerspost.com

Crankshaft Parts, Function, Types, Diagram & More [PDF] Crankshaft Grinding Machine Working Principle the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring and eccentric. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines arbor to accommodate. crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to. Crankshaft Grinding Machine Working Principle.

From ecomachinetools.com

Crankshaft Grinders CNC Crankshaft Grinding Machine Crankshaft Grinding Machine Working Principle crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to rebuild the part. the work was performed with grinding machine type db12500, equipped with sinumerik 840d control system, as well as measuring and eccentric. the crankshaft grinding wheel is secured with a hub, balanced and mounted to the machines. Crankshaft Grinding Machine Working Principle.